Optical Components

Optical Components Cylindrical Lenses

Cylindrical Lenses

MLOptic is dedicated to designing, developing, and manufacturing high-precision cylindrical lenses to meet your specific needs. We offer a variety of cylindrical lens shapes, including traditional plano-convex, plano-concave, convex, concave, bi-convex, bi-concave, single-axis cylindrical lenses, as well as unconventional hyperboloid-cylindrical lenses, and toroid mirrors.

Cylindrical lenses, due to their unique geometric structure, can produce a linear focus rather than a focal point, making them widely used in various designs and applications.

Materials

We have extensive experience working with a broad range of materials, including:

· Common Glass (Schott, Ohara, Hoya, CDGM)

· Fused Silica

Manufacturing Capability

· Max Diameter: 100 mm

· Diameter Tolerance: +0/-0.01 mm

· Surface Quality: 10-5

· Radius: 5mm to ∞

· Radius Tolerance: ±0.002 mm

· Form Error: λ/10

· Centering: 0.005 mm

· Coating: Broadband AR, V-coat, and mirror coatings, as well as all kinds of customized optical coatings

Testing Capability

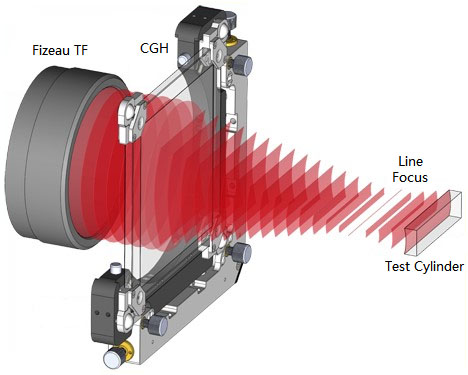

We use Zygo interferometers with Computer Generated Holograms to test our cylindrical lenses. The maximum measuring aperture is φ95mm, accurate to λ/10.We offer CGH testing for surface profile accuracy.

Why Choose MLOptic

Original Equipment Manufacturers (OEMs) widely rely on cylindrical mirrors in various fields such as holography, optical spectroscopy, and laser line scanning to achieve their precise optical systems. MLOptic, with its advanced manufacturing technology and rich industry experience, is committed to solving the various challenges that OEMs face in the manufacturing of precision optical components. We consistently provide the highest quality cylindrical optical components, helping our customers achieve excellent optical performance and product reliability.

Contact us to discover the difference that precision engineering can make for your optical needs. Learn more about our cylindrical lenses and how they can enhance your projects.