Optical Components

Optical Components Aspheric Lenses

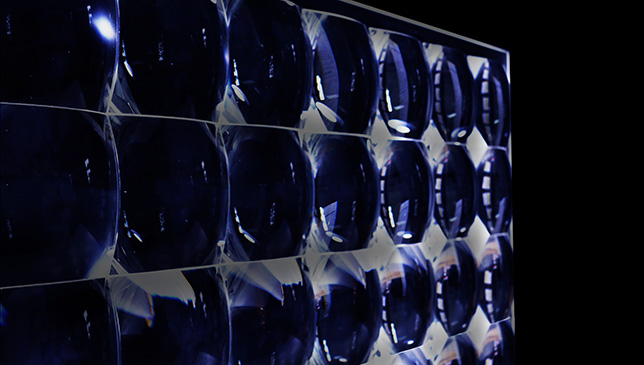

Aspheric Lenses

MLOptic specializes in the design and manufacturing of aspheric lenses, where at least one surface is rotationally symmetric about the optical axis but is not spherical in nature. These lenses are widely used in various optical systems and allow for improved performance with a reduced number of optical elements.

Our aspheric lenses are made from glass and quartz materials (typically using materials from SCHOTT, OHARA, or CDGM). Moreover, we offer aspheric lenses of IR materials (such as ZnS, ZnSe, Ge, Si) and metal mirrors.

Classifications:

· Single-sided aspheric lenses

· Bi-aspheric lenses

· Off-axis aspheric lenses

For glass and quartz materials:

The possible diameter range is 10mm to 300mm, with a minimum concave radius of 50mm.

For IR materials:

The possible diameter range is 2mm to 140mm.

Technology & Manufacturing Equipment:

CNC grinding, CNC polishing, diamond turning, MRF, IBF

Metrology & Quality Assurance:

MLOptic offers optical metrology, including surface profilometry and interferometry to verify specifications are met for fabricated optics. We perform 100% inspection on all optical components during the manufacturing process and provide inspection reports proportionally.

· Contact Measurement: Taylor Hobson Pgi1250 Profiler

Maximum measurable aperture: 200mm

· Non-contact Measurement: Lupho Scan

Fast non-spherical optical non-contact 3D interferometric scanning, with a maximum measurable diameter of 420mm and a measurement accuracy of ±50nm

· Interferometer Measurement: 6-inch Aperture Stitching Interferometer (SSI)

Maximum measurable aperture: 300mm, with a spherical aberration of less than 0.12mm

· CGH Inspection: Custom designed for different lenses

Manufacturing Capability:

· Diameter: 5.0mm to 300.0mm

· Minimum Radius of Curvature: Convex 10mm; Concave 50mm

· Materials: Optical glass, quartz glass, Germanium (Ge), Silicon (Si), Zinc Sulfide (ZnS), Zinc Selenide (ZnSe)

Manufacturing Tolerances:

· Diameter Tolerance: +0.00 / -0.02mm

· Surface Quality: 20/10

· Radius of Curvature (Convex): 10mm – ∞

· Radius of Curvature (Concave): 50mm – ∞

· PV (Peak-to-Valley): λ/10 @ 633nm

Why Choose MLOptic Aspheric Lenses?

· Innovation: We are at the forefront of optical technology, constantly innovating to bring you the best products.

· Reliability: Our lenses are built to last, ensuring consistent performance over time.

· Customer Service: Our dedicated team is always ready to assist you with any questions or concerns.

Contact us today to discover the difference that precision engineering can make for your optical needs. Learn more about our aspheric lenses and how they can enhance your projects.