Optics Capabilities

Optics Capabilities Automation

Automation

We excel in the automation of optical component manufacturing and inspection, ensuring the consistency and stability of product quality.

Automated Manufacturing Capabilities:

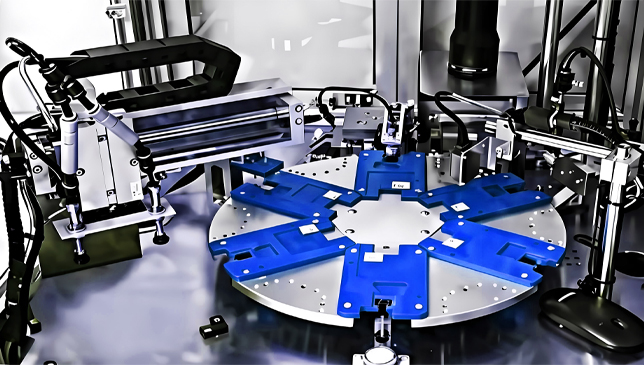

We possess advanced automated production equipment, such as automatic bonding and automatic silk screening machines. These not only enhance production efficiency but also ensure precision and repeatability in the manufacturing process, thereby guaranteeing the consistency and stability of optical component quality.

Automated Inspection Capabilities:

In the realm of automated inspection, we achieve excellent Measurement System Analysis (MSA), ensuring the consistency of inspections and production efficiency. Equipment such as automatic resistance measurement devices and automatic dimension and surface shape measurement tools enable precise measurements of optical components, ensuring that the quality of delivered products meets stringent standards.