Optics Capabilities

Optics Capabilities CNC Shaping Optics

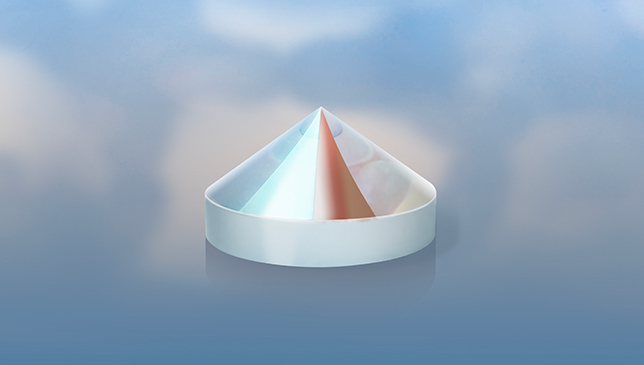

CNC Shaping Optics

MLOptics' custom processing services for special-shaped optical components not only meet customers' diverse needs for the functionality, performance, and size of optical devices but also get involved from the stage where customers propose product concepts. They provide technical assistance and maintain close communication with customers to clearly understand their needs and can quickly offer optical advice.

The six categories of special-shaped processing are:

1. Special-shaped prism forming, with dimensional requirements of ±0.1mm, edge breakage <0.1mm, and chamfering <0.2mm;

2. Special-shaped lens forming, with dimensional requirements of ±0.05mm, edge breakage <0.1mm, chamfering <0.3mm, and flatness/contour <0.05mm;

3. Special-shaped aspheric lens cutting, special-shaped side cutting, high-precision positioning, edge breakage <0.1mm, and chamfering size <0.3mm;

4. Planar mirror forming, with inner and outer contour requirements of 0.2mm, edge breakage <0.1mm, chamfering size <0.3mm, and roughness <0.9um;

5. Special-shaped prism microcrystal glass multi-angle side cutting, high-precision positioning, edge breakage <0.1mm, and chamfering size <0.3mm;

6. Special-shaped prism multi-angle side cutting, high-precision positioning, dimensional requirements of ±0.1mm, edge breakage <0.1mm, and chamfering size <0.3mm.